Plasma Green Filter

The core objective of the Paris Climate Agreement of December 13, 2015, which is binding for all countries, is to drastically reduce greenhouse gases. This primarily concerns CO2 emissions, but also other greenhouse gases. In the context of exhaust gas aftertreatment, emission limits are placing ever higher demands on exhaust gas technology. Soot reduction, effective desulphurization and NOx conversion are particularly important in this context.

The sustainable contribution of future-oriented companies is often associated with increased acquisition and maintenance costs. However, it is important to bear this in mind: Modern technologies are increasingly offering innovative solutions, including in the field of exhaust gas aftertreatment. In contrast to established processes, plasma-based exhaust gas cleaning is carried out without the use of scrubbing water and without the addition of expensive operating materials such as quicklime or the reducing agent AdBlue. The new plasma process therefore makes cleaning the exhaust gas stream more space-saving, simpler and more cost-effective.

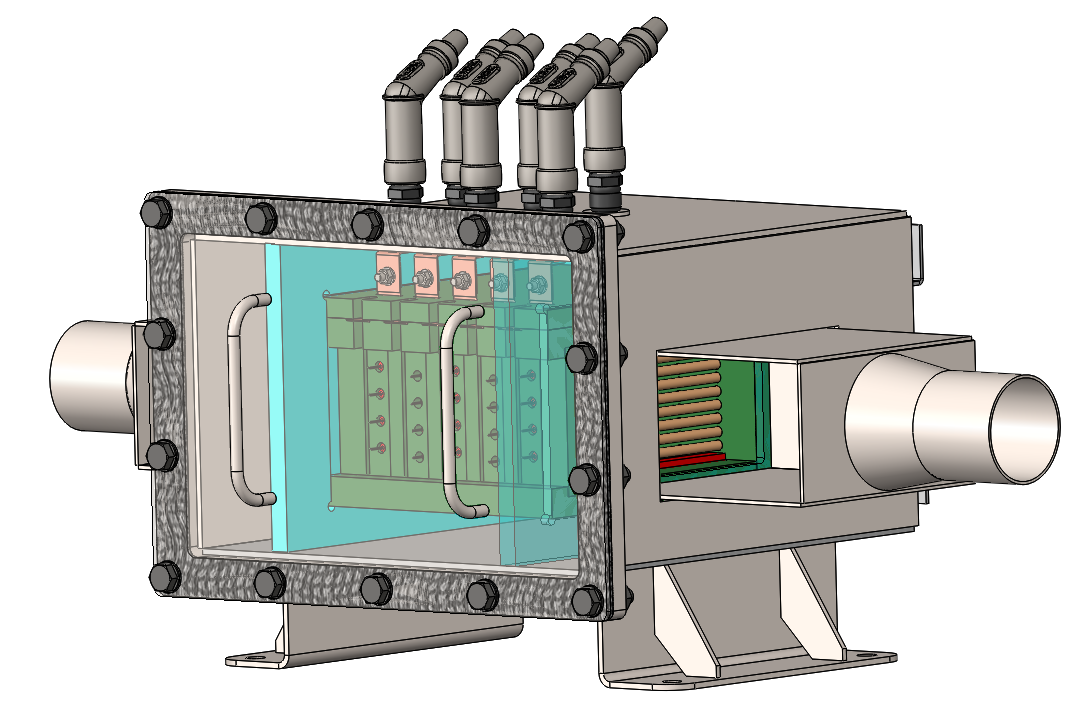

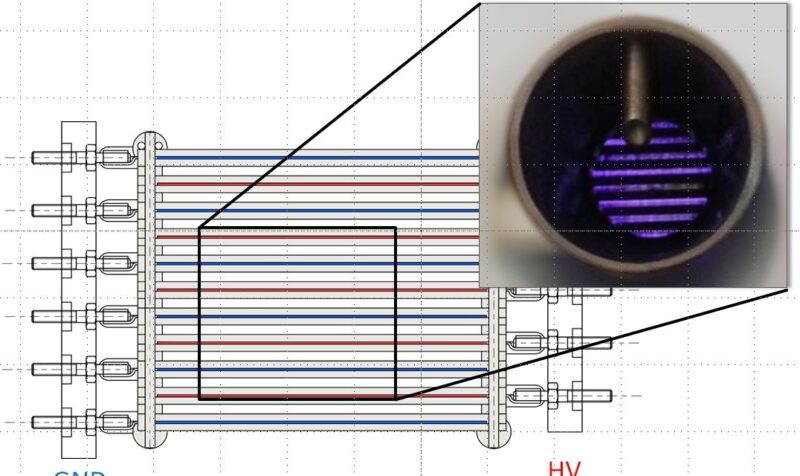

The functional principle

- Exhaust gas is passed through the reactor with low flow resistance

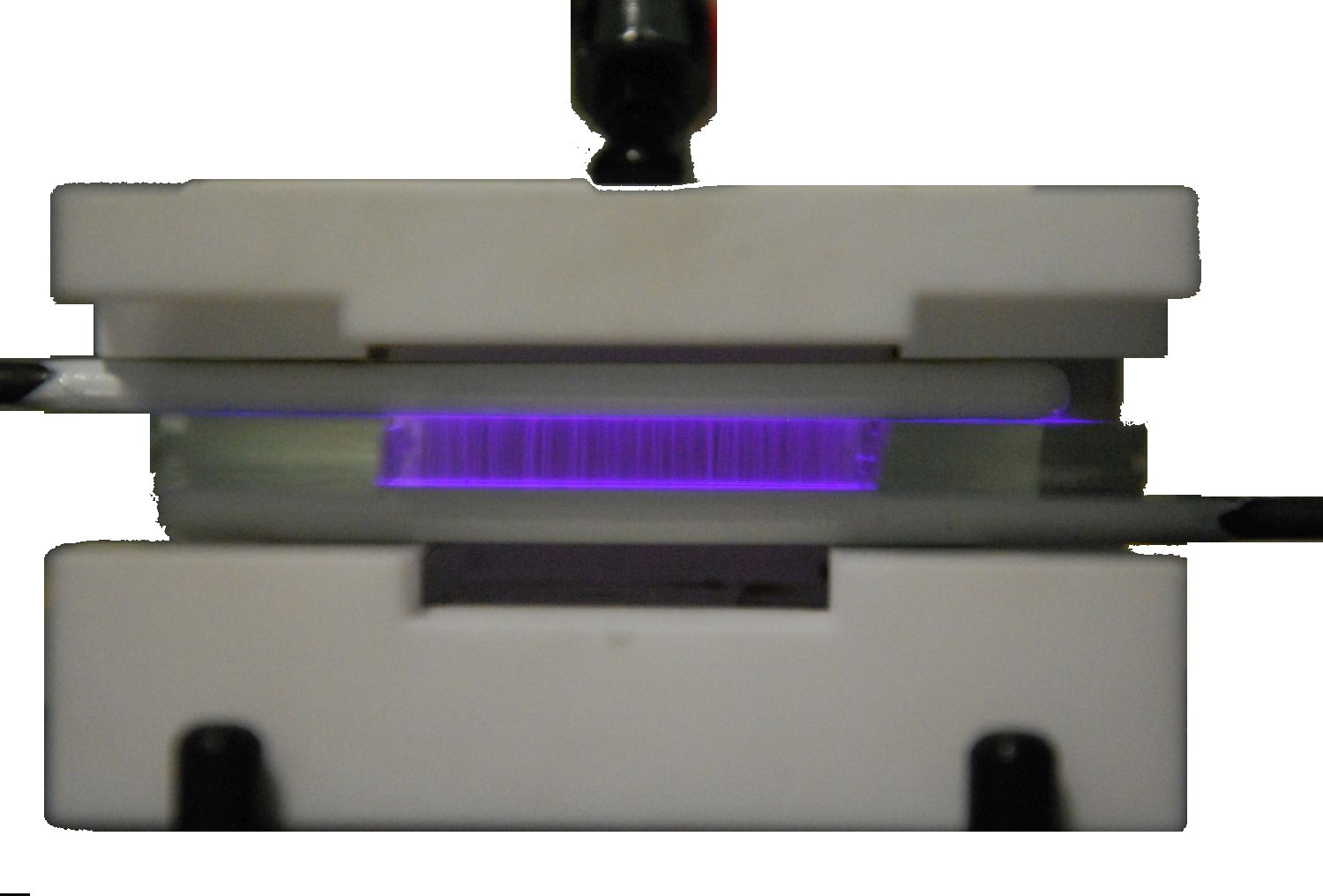

- A dielectrically impeded discharge breaks down the exhaust gas into fragments

- Fragments combine to form natural air components

Why is it called a soot particle cleaner and not a filter?

Unlike conventional soot particle filters, the plasma soot particle cleaner has no filter and therefore no medium that can become clogged with soot particles over time. All disadvantages associated with a filter medium can therefore be considered irrelevant.

How it works

The plasma cleaner process is based on dielectrically impeded discharges and therefore guarantees effective cleaning of even the smallest soot particles. The low space and energy requirements meet customer requirements, as does the low flow resistance, which cannot be achieved even with current technologies.

Area of application

Any vehicle with a diesel engine can be equipped with the plasma soot particle cleaner, as it can be scaled as required.

Cooperation TH Clausthal x Weihe Gmbh

Against this background, Weihe GmbH has developed an innovative plasma soot particle cleaner for diesel engines together with the Clausthal University of Technology, which eliminates the disadvantages of a conventional diesel particulate filter.